Our integrated team provides turnkey prototyping and production services, including: machining, metal fabrication, casting, injection molding, and much more. With quality finishing options we make it easy to get the parts you need without chasing down multiple vendors.

With over a hundred 3-axis and a dozen 5-axis CNC machines along with CNC lathes, wire cut EDM, and sink/plunge EDM machines, we can create precisions parts from a wide variety of materials

Our full line of sheet metal prototype and production capabilities include: large format laser cutting, a turret punch press, CNC bending, riveting, tapping, and welding.

Hydraulic and mechanical presses ranging from 45T to 250T allow us to draw with or without custom tools depending on design.

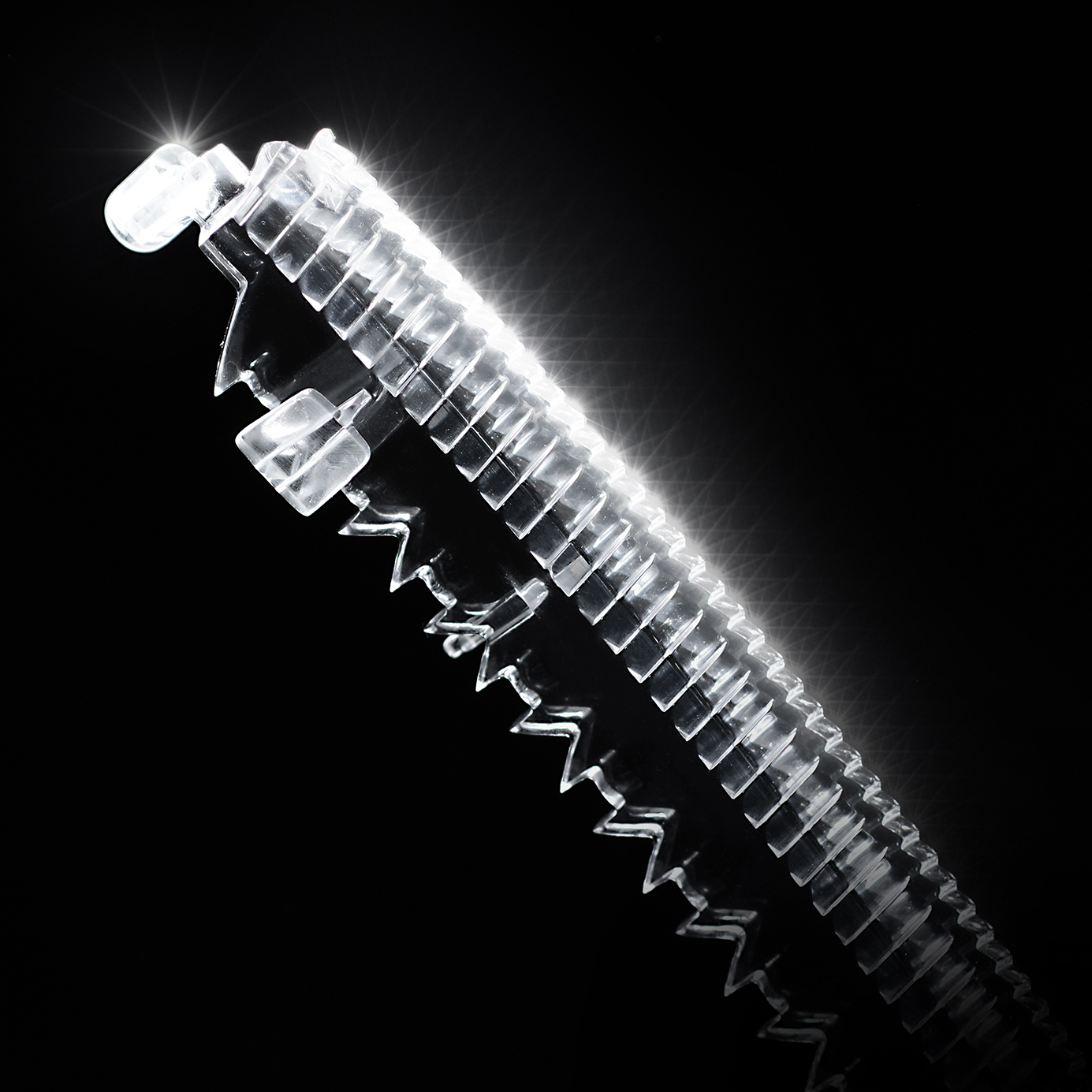

Whether you’re looking for single, multi-cavity, or overmolded parts, Firsthand Fab is able to create highly detailed molds in rigid ABS-like or soft rubber material options.

Looking to produce 10K or 100K plastic parts but only need 1,000 to start? Firsthand is here to help. Our tooling modifications are affordable and our lead times are solid.

We are able to create high quality and cost-effective rapid tools with short lead times. Firsthand Fab has made and shipped precision molds and parts as large as car bumpers.

With various bed sizes available and a variety of materials to choose from, our SLA and SLS printers can handle most jobs; however, with our efficient CNC process you may want to consider machining your plastic parts. Firsthand is always happy to quote both options.

Depending on material selection, many 3D printed parts can be hand finished and painted to match a variety of appearances from matte to gloss in the color of your choice.

Firsthand creates expertly crafted appearance models that show off your design vision. Combining our wide array of processes and materials, we’re able to achieve convincing parts with attractive lead times and prices.

With a wide variety of finishing services offered in-house, Firsthand Fab is able to serve as a one-stop shop on just about any job. No matter the desired properties or appearance of the coating, the experts at Firsthand can help you get the perfect finish.

Color Matching – Looking to use a specific color or metallic finish? Send us a sample and using Pantone or R.A.L (European standard) we are able to get it right the first time.

Texture – Want your prototype parts to feel like the real thing? Whether casting or machining, our finishing team can make your part look and feel like a production part with mock mold textures and soft touch applications.

Rubber / Elastomer – Need some flexibility? Firsthand has the ability to mold almost any durometer.

Samples – Not sure exactly what finish you’re looking for? We have samples available by request.